Vapor Intrusion Mitigation at the Former Plumley Rubber Company Site

The former Plumley Rubber Company Site, a 9-acre industrial property located in Morristown, Tennessee, experienced significant environmental contamination caused by historical manufacturing processes between 1961–1975. Over time, hazardous organic chemical vapors, primarily trichloroethylene (TCE), accumulated beneath the building’s concrete slab creating a vapor intrusion condition inside the structure. By 2015, indoor air quality samples confirmed TCE concentrations exceeded U.S. EPA screening levels, creating an urgent need for intervention.

To address these risks, CCI (Cannon & Cannon, Inc.) partnered with the Industrial Development Board (IDB) of Morristown and secured a $500,000 Brownfield Redevelopment Area Grant (BRAG) through the Tennessee Department of Environment and Conservation (TDEC). This funding supported the design and installation of a comprehensive vapor mitigation system that is protective of human health, ensures compliance with TDEC requirements, while positioning the site for future redevelopment.

Project Goals and Challenges

The key objectives of the project were:

- Eliminate hazardous vapor intrusion into the building through a robust vapor mitigation solution.

- Engage with stakeholders through a Community Involvement Plan, ensuring transparency and public trust.

- Monitor and document construction activities to meet BRAG and TDEC requirements.

- Monitor indoor air quality post construction to ensure indoor air quality requirements are met.

The primary challenges included:

- Elevated TCE concentrations rising by approximately 200% between 2015 and 2024.

- Aging infrastructure, including a 35,000-square-foot concrete floor slab with multiple defects from historical use and significant sub-surface contamination.

- Community concerns over environmental safety and future use of the property.

Greg Jernigan, part of CCI’s Environmental Team, breaks down the remediation of the 9-acre site in Morristown, TN, contaminated by TCE vapors from 1961-1975. Using a $500,000 TDEC Brownfield Grant, CCI deployed a sub-slab venting and Land Science Retro-Coat™ system to fight rising contamination and prep the site for redevelopment.

CCI’s Technical Solution – Multi-Stage Vapor Intrusion Mitigation System

CCI, in partnership with R&S Logistics, vapor mitigation contractor MTN-INC and technology provider Land Science, designed a two-stage system combining active venting and a chemical vapor barrier coating.

Sub-Slab Venting System

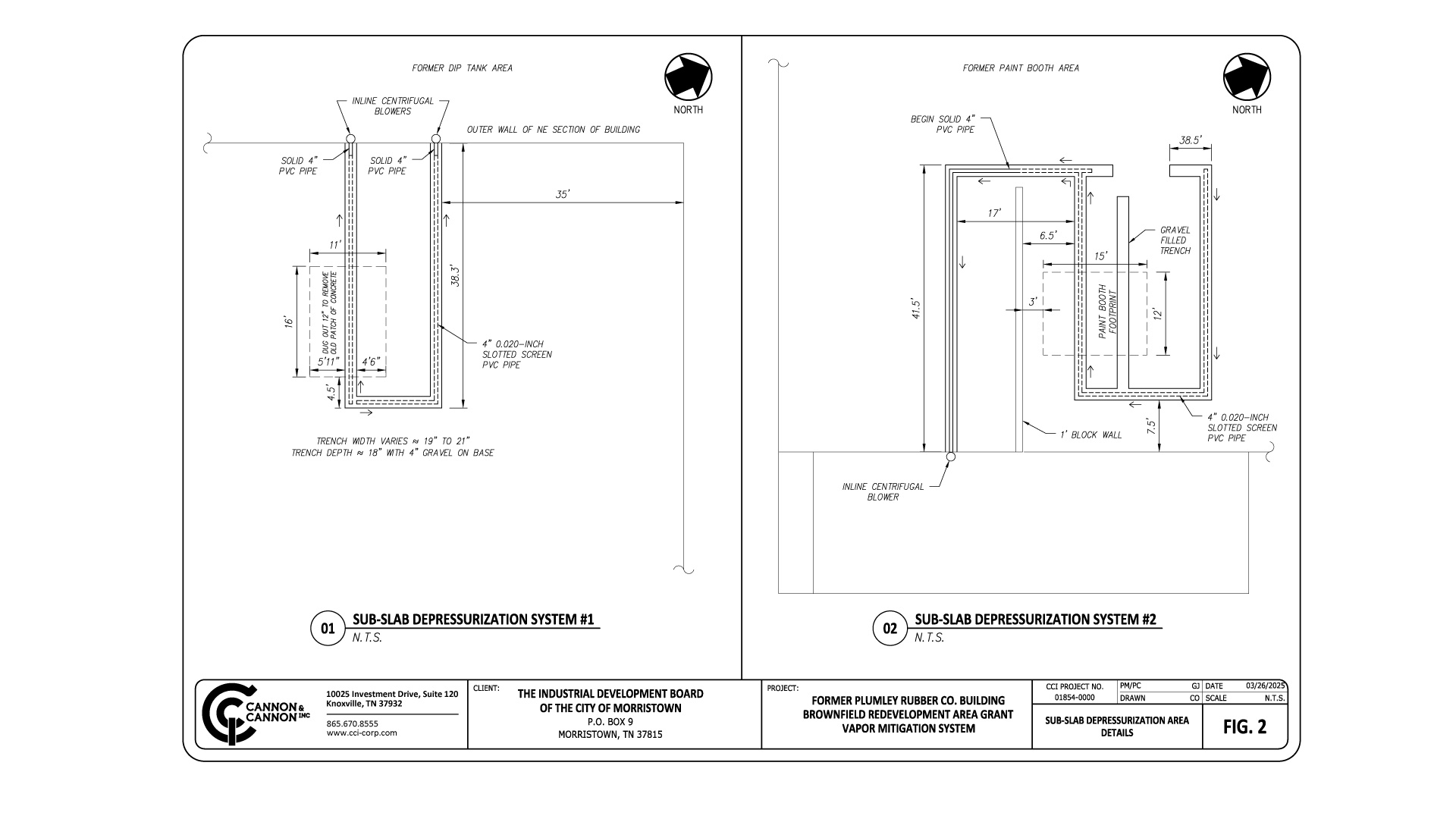

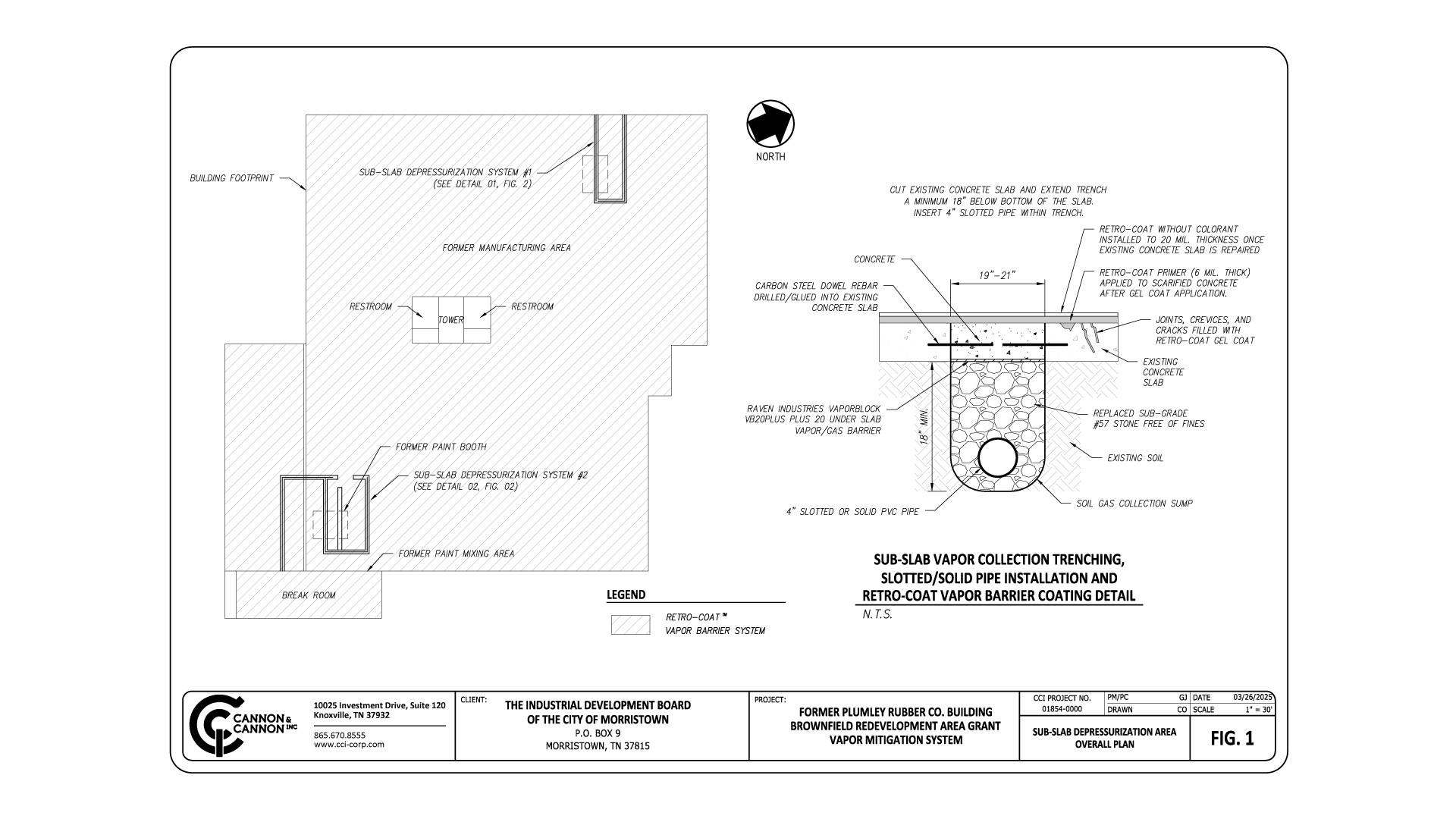

A network of 300 linear feet of sub-slab perforated collection piping was installed within crushed stone suction pits beneath two sections of the building with the highest TCE concentrations. This network of pipes is connected by three sections of solid riser piping extending above the roofline of the building that are outfitted with inline centrifugal blowers that create negative pressure under the building slab, actively venting vapors to the outside air in order to reduce concentrations beneath the floor.

- Trenches were cut and excavated to a depth of 18 to 21 inches beneath the existing slab.

- Clean #57 stone was placed as a base layer, and a horizontal run of 4-inch Schedule 40 PVC piping was laid.

- Land Science’s TerraShield™ vapor barrier material was placed on top of the stone, followed by a spray application of Nitra-Seal™ to provide an additional layer of vapor protection.

- The trenches were sealed with 4,000 psi concrete, reinforced with #4 rebar, to restore slab integrity.

Chemical Vapor Barrier Coating

The Retro-Coat™ system from Land Science was applied across the 35,000-square-foot slab to provide a durable, impermeable vapor barrier. This multi-step process included:

- Concrete Cutout and Replacement: Cut out visual damaged and/or bulging areas of the concrete related to historical use.

- Surface Preparation: Scarification of the concrete slab using automated and filtered grinding tools to remove imperfections and ensure adhesion.

- Gel Coat Application: The dense structure of the coating eliminates pathways for vapor intrusion by sealing off micro-cracks and pores in the slab.

- Primer Application: A two-coat epoxy primer that bonds with the concrete forming a strong mechanical and chemical bond that prevents delamination.

- Retro-Coat Application: The two-part epoxy barrier forms an impermeable layer resistant to TCE vapors and other volatile organic compounds (VOCs).

The chemical resistance and durability of Retro-Coat™ ensure long-term protection against vapor intrusion. Its dense epoxy structure blocks vapor molecules, while the primer ensures a strong bond to the slab for enhanced longevity.

Community Engagement

CCI implemented a Community Involvement Plan to meet BRAG grant requirements and build public trust:

- Weekly Notices: Published in the Citizen Tribune for four weeks to inform the community about site contamination, remediation activities, and redevelopment plans.

- Public Meeting: Hosted a local event to provide stakeholders with detailed information and address concerns.

- Site Signage: Erected a sign at the entrance to the Plumley facility detailing the site’s listing project funding under the TDEC Brownfield Redevelopment Area Grant process and under TDEC oversight of the vapor mitigation project.

Results

Elimination of Vapor Intrusion

The combination of sub-slab venting/depressurization and the Retro-Coat™ chemical vapor barrier effectively blocks hazardous vapors, protecting human health.

Environmental Compliance

The project meets the standards set by TDEC and the U.S. EPA for vapor intrusion mitigation.

Community Redevelopment

The site is now safe for re-occupancy, creating opportunities for economic growth and revitalization of a once-vacant property.

Health and Safety

Long-term exposure to TCE is linked to adverse health effects, including cancer and neurological damage. This system ensures a safe working environment for future occupants.

Sustainability

Land Science’s Retro-Coat™ vapor barrier technology provides durable and cost-effective protection for decades, ensuring the site’s usability into the future.

Through strategic engineering and environmental expertise, CCI successfully designed and oversaw the implementation of a comprehensive remedial solution at the former Plumley Rubber Company Site. By mitigating hazardous vapor intrusion and aligning with the goals of the TDEC BRAG program, this project serves as a model for effective brownfield redevelopment. It underscores the value of innovative vapor mitigation technologies, meaningful community engagement, and the smart application of grant funding to support site revitalization and public health. Looking to address environmental challenges on your site? Contact our team to learn how CCI can support your project from concept to completion.